Heusinkveld Sim Handbrake V2

Heusinkveld Sim Handbrake V2

Sim Motion

Free Shipping On Orders Over $300.

Couldn't load pickup availability

Share

Description

Description

The Heusinkveld Sim Handbrake V2 is a USB-connected, pressure-sensitive simulator handbrake utilizing load cell technology for precise, progressive control. Featuring Heusinkveld’s proprietary elastomer springs and SmartControl software compatibility, it offers fully customizable output curves and ergonomic mounting options. The handbrake supports both horizontal and vertical lever orientations and includes an optional adapter plate with yaw adjustment for aluminum profile rigs.

Features

-

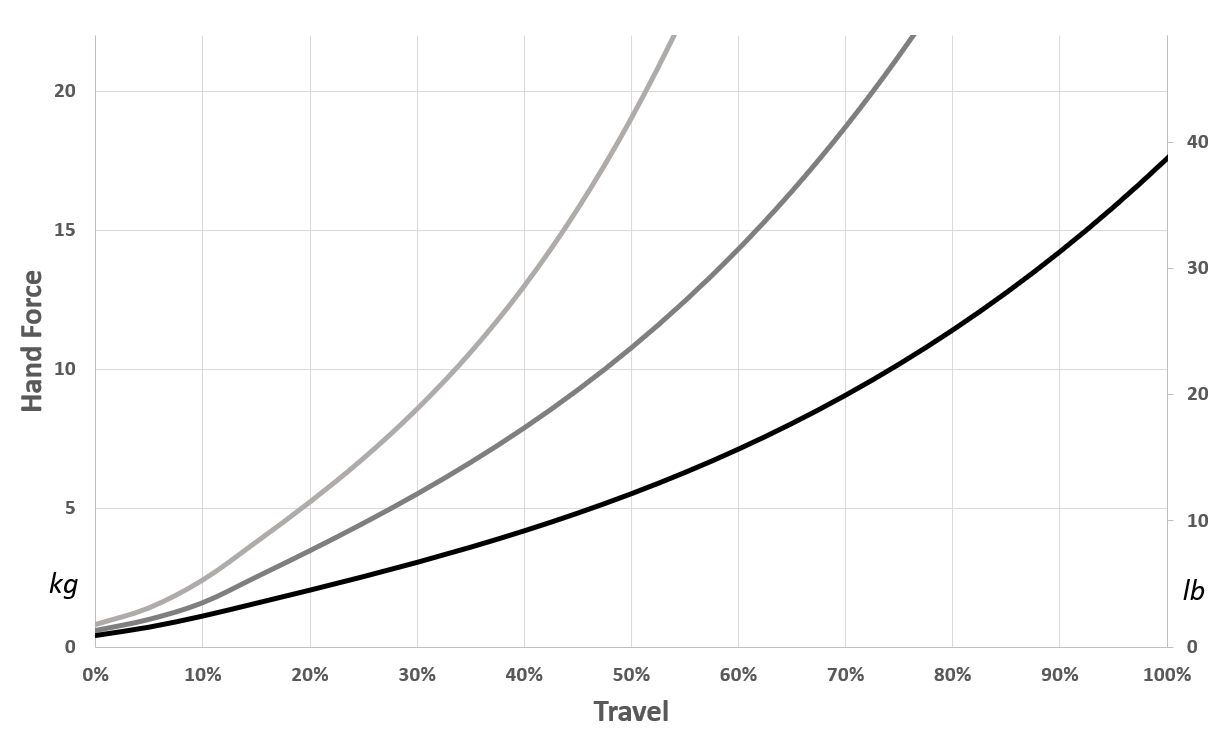

120kg load cell providing up to 22kg of force at the lever

-

Heusinkveld SmartControl support for custom output mapping

-

Horizontal or vertical lever orientation with 26° fine-tune adjustment

-

Optional adapter plate with up to 22.5° yaw adjustment for aluminum profiles

-

Integrated electronics with EMC compliance

-

USB connectivity for PC use

Specifications

-

Resistance: 2-stage spring system (adjustable preload and travel)

-

Elastomers: 3 included for soft, medium, or stiff resistance feel

-

Lever Orientation: Horizontal or vertical with angle adjustment

-

Mounting Options: Base mountable in both orientations; adapter plate included

-

Output: Linear force measurement via SmartControl, customizable without recalibration

-

Connection: USB cable included

Built for sim racing enthusiasts seeking a durable, fully adjustable load cell handbrake with customizable performance and flexible mounting options.

Shipping policy

Shipping policy

Shipping and payment terms

Payment and shipping

The following conditions apply:Shipping conditions

The delivery takes place within USA and Canada. *Canadian Duties and Taxes are not covered, you will be responsible for all charges*

Delivery times

As far as no other time limit is stated in the respective offer, the delivery of the goods within the country will take place within 3 - 5 days, in case of foreign deliveries within 5 - 7 days after conclusion of the contract (in case of agreed advance payment after the date of your payment instruction).

Please note that there is no delivery on Sundays and holidays.

If you have ordered articles with different delivery times, we will send the goods in one common shipment, unless we have made different agreements with you. In this case the delivery time is determined by the article with the longest delivery time you have ordered.

If you collect the goods yourself, we will inform you by e-mail about the availability of the goods and the collection options. In this case no shipping costs will be charged.

Accepted payment options

- Cash payment on collection

- Prepayment by bank transfer

- Payment by credit card

- Payment by PayPal

- Payment by PayPal Express

Further details on payment

If you pay by credit card, your credit card account will be charged upon conclusion of the contract.

If you have any questions, you will find our contact details in the imprint.

Return policy

Return policy

General Return Policy

We accept returns within 14 days of receiving your order, provided the item meets the following conditions:

- It must be undamaged, unused, and in resalable condition (no markings, labels, or tape directly on the product box).

- It must be in its original packaging and include all accessories.

- Opened items may be returned only if unused and in perfect condition.

- All returns require prior authorization. Please contact info@simmotion.com before returning any item to receive a Return Merchandise Authorization (RMA) number. Unauthorized returns may be refused.

All returns are subject to a restocking fee of $10 or 15% of the item price, whichever is greater. This fee covers handling, inspection, and processing of the return before resale.

Return Shipping & Fees

- Customers are responsible for all return shipping costs unless the item is considered defective.

- Shipping fees are non-refundable, as they are paid directly to the carrier (UPS, FedEx, USPS) and cannot be recovered.

- If your order originally qualified for free shipping, the original shipping cost will be deducted from your refund.

- Items must be properly packed in an outer carton to avoid damage in transit. Do not place labels or tape directly on the product box.

Return to Sender / Refused Shipments

If a package is returned to Sim-Motion Inc. due to an incorrect address provided by the customer, failure to accept the package, refusal of delivery, or if you'd like to request a return to sender through UPS, the following fees will apply:

- Outbound Shipping Fee: The original shipping cost of the order (even if the order qualified for free shipping).

- Return to Sender Processing Fee (UPS): $21.

- Sim-Motion Restocking/Processing Fee: $25.00.

The total of these fees will be deducted from your refund.

If you would like the package reshipped, you will be responsible for the new shipping charges.

Please ensure that your shipping information is accurate at checkout to avoid these additional costs.

If Your Return Does Not Qualify

- If an item you returned does not meet our return requirements, you may request to have it sent back to you at your expense.

- If we do not receive a response within 7 days, the item will be discarded.

Defective or Damaged Products

If you receive a defective item or an incorrect shipment, contact us at info@simmotion.com within 14 days to begin the return process.

- First 14 Days: We cover Standard/Ground return shipping for defective or incorrectly shipped items. If you choose expedited return shipping, you are responsible for the cost difference.

- After 14 Days: The customer is responsible for return shipping costs.

- All returns require prior authorization. Please contact info@simmotion.com before returning any item to receive a Return Merchandise Authorization (RMA) number. Unauthorized returns may be refused.

Inspection & Resolution

- Upon receipt, we will inspect and test the product. If a defect is confirmed, we will offer a repair, replacement, or refund.

- If no defect is found, the customer will be responsible for return shipping and any applicable labor fees.

Damaged in Transit

- If your package arrives damaged, we recommend that you refuse shipment for return if possible. If you have received it, you must report it to us within 48 hours with photos of the packaging and item. DO NOT discard cartons, packaging, etc or we may not be able to file an insurance claim.

- Claims filed after this period or that do not file this criteria, may not be eligible for a refund or replacement.

Non-Refundable Items

We do not accept returns or refunds for the following:

- Items not purchased directly from Sim-Motion Inc.

- Items that are damaged due to misuse, negligence, or modification (e.g., improper installation, exposure to extreme conditions).

- Items that show normal wear and tear or have exceeded their reasonable life expectancy.

- Personalized or custom-made products.

- Digital products or software downloads.

- Gift cards.

If a product is damaged or missing original packaging, it does not qualify for a refund. Repairs can be arranged, but labor and parts costs will apply.

Order Modifications & Cancellations

Modifying an Order

Orders are processed immediately upon placement, making modifications difficult. If you need to update shipping details or correct an issue, please contact us as soon as possible. We will do our best to accommodate your request, but changes are not guaranteed.

Canceling an Order

- Orders can only be canceled before they have shipped.

- A 5% processing fee applies to all cancellations to cover transaction fees and administrative costs.

- If your order has already shipped, it cannot be canceled. You may return the item following our return policy.

Refund Processing

Refunds will be issued to your original payment method after the returned item has been received, inspected, and approved.

- Refunds exclude shipping fees and the 15% (or $10 minimum) restocking fee.

- If your return does not meet policy requirements, Sim-Motion Inc. cannot guarantee a refund.

- Processing Time: Refunds will be processed within 5–7 business days after return approval. Please allow 1–2 billing cycles for the refund to appear on your statement, depending on your payment provider.

Questions?

For assistance with returns, defective products, or cancellations, please contact us at info@simmotion.com.

Safe and Secure Payments. Easy returns.100% Authentic products.

Bundle Configurator

Elevate your sim racing experience with our customized setup options! Personalize your gear with the essential products you need and enjoy a 5% discount on your purchase.